The durable medical equipment supply industry is growing rapidly. But success in this field has been elusive for many DME/HME businesses because making it in this sector requires in-depth industry knowledge. Having been in the market for decades, the information we share about how to succeed in the DME industry is based on our struggles and successes.

In this article, you’ll learn why your home medical equipment company is stagnating while others are growing. More importantly, you’ll learn how to fix it.

Scroll down and find out the secrets of successful durable medical equipment business and how they overcome hurdles in the industry to emerge as the fastest-growing companies.

- Creating a patient-centric experience improves satisfaction, loyalty, and operational efficiency in DME businesses

- Optimizing inventory management with digital systems and drop shipping reduces costs and ensures timely equipment delivery

- Streamlined revenue cycle management (RCM) prevents claim denials, maintains cash flow, and supports business growth

- Automation across all processes boosts productivity, eliminates errors, and allows DME providers to scale effectively

1. Establish a Patient-Centric DME Experience

It’s time to look beyond the traditional DME enterprise approach, where patients came second after business. To withstand market shocks, unfavorable government regulations, and other DME/HME industry setbacks, you must tailor your services to meet patients’ expectations.

You can create a patient-centric DME experience through the implementation of the following steps:

- Automate the patient-intake process. Moving away from manual processes that usually require patients to present themselves physically in your facility gives patients flexibility they can’t get anywhere else. Digitize the intake process so patients can sign up and apply for DME devices from an online portal. With an automated patient-intake process, patients can make online appointments, submit their documents online, and wait for order fulfillment without leaving the comfort of their homes.

- Expedite document verification. One of the most significant pain points for DME clients is the back-and-forth insurance verification that lengthens the time for equipment approval. You can shorten this time by automating patient data verification.

- Enhance communication. Patients must be kept in the loop of what’s happening to help them know when they can receive equipment. This allows those in the front-end office to correctly set up patients’ details the first time. A good idea would be to ensure your team has real-time information about payments and order status to provide patients with accurate updates.

- Streamline payment collection. The effective collection is not only an ingredient for business growth but a catalyst for improving provider-patient relationships. Correctly billing a patient and keeping track of how much the patient owes facilitates seamless ordering and delivery of equipment. Automating the payment process eliminates potential errors that could delay the delivery of much-needed equipment and lead to patient dissatisfaction.

2. Optimize Inventory Management

The supply chain for DME businesses is a complex process that involves multiple parties and numerous verifications at each stage. Your success in the DME industry depends on how well you manage your inventory. Ditch manual systems and adopt real-time tracking of inventory items instead.

Live asset tracking allows you to have accurate ETAs of equipment. The following steps help to build an efficient inventory system in your HME/DME supply:

- Replace manual inventory systems with digital systems with real-time tracking and order management capabilities.

- Maintain the correct inventory at all times to reduce costs.

- Find the right balance between inventory on hand and incoming inventory.

- Embrace digital signature at the curbside.

- Use DME/HME inventory management software.

Consider drop ship vendors. Traditionally, DME providers ordered equipment from manufacturers, stored the equipment, and shipped it to patients. This model is bureaucratic, labor-intensive, and costly.

Drop shipping is a cost-effective strategy for any DME supplier who wants to pass shipping and storage costs to equipment vendors. When you get an order from the patient, you contact your vendor to ship the equipment directly to the patient.

Drop shipping helps succeed in the durable medical equipment industry because it answers key questions . How can you get medical devices in a short period of time? How quickly can you make and process orders? How can you source medical equipment inexpensively? Drop shipping leads to success because it is efficient, fast, convenient, and less costly.

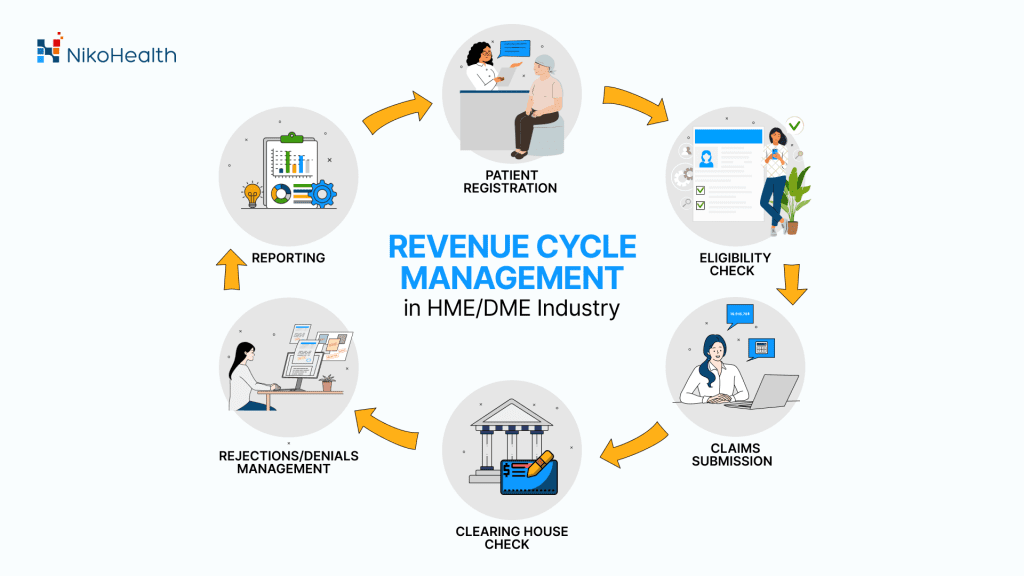

3. Streamline Revenue Cycle Management (RCM) Processes

Proper revenue cycle management is critical to timely and accurate submission and processing of claims – errors in billing increase denials, which negatively affects the cash flows. The inconsistent flow of money in a DME supply business hampers timely delivery of equipment, and any delay eventually ends up affecting the patient in one way or the other.

For astute business owners in the durable medical equipment industry, staying profitable and sustainable means maintaining a solid RCM process while at the same time growing your client base. A smooth and efficient RCM process prevents overcharging/undercharging of patients, denial of claims, and time wastage in following up on copayments.

For efficient RCM and better customer satisfaction, build an electronic patient registry system that integrates with existing systems like electronic health records (EHRs).

💡 You May Also Be Interested In: DME Compliance in 2026: Latest Updates

4. Automate Every Process of Durable Medical Equipment Business

Surviving in the DME industry means taking care of both the patient and your business. And y our business will stagnate if you don’t move away from outdated manual systems. Your competitors are already navigating their problems by leveraging automation, so don’t be left behind.

As critical stakeholders in the DME/HME business, we’ve seen how automation transforms healthcare organizations. Here are ways in which automation boosts your bottom line:

- Fast order fulfillment and real-time inventory control

- Elimination of common errors that lead to denials

- Smooth patient intake and insurance eligibility verification

- Better management of orders and supplies

- Generation of useful analytics for data-driven decision making

- Elimination of paperwork, which increases productivity and reduces errors

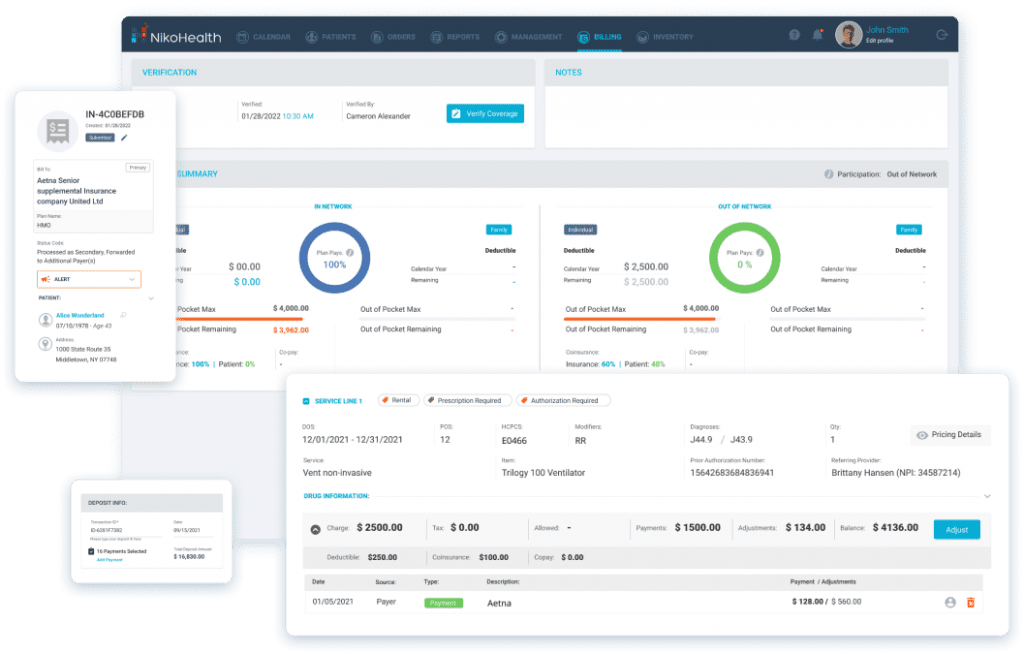

How NikoHealth Can Help You

NikoHealth provides DME businesses with tools to streamline operations, reduce administrative burdens, and improve patient satisfaction. Our solutions integrate automation, inventory management, and revenue cycle management to help your business grow efficiently.

With NikoHealth, you can:

- Automate patient intake and insurance verification for faster processing

- Track inventory in real time and manage orders seamlessly

- Enable drop shipping to reduce storage and shipping costs

- Generate actionable analytics for data-driven decision-making

- Minimize billing errors and prevent claim denials

- Maintain compliance with industry regulations while improving productivity

Final Takeaway

Good news – DME/HME businesses are bound to grow. As the U.S. and other nations across the world grapple with an aging population, more and more people need assistive devices and medical equipment. You can succeed in the DME industry by being on the front line, showcasing efficiency and reliability. For the best results, embrace technologies like DME software and adopt automation as part of your daily business routine.

FAQs

What does DME stand for?

DME stands for durable medical equipment, which refers to medical devices designed for long-term use to assist patients in daily living or recovery. DME plays a critical role in helping patients maintain independence, manage chronic conditions, and improve overall quality of life, making it a cornerstone of home healthcare and long-term care services.

How can small DME businesses compete with larger suppliers?

Small DME businesses can compete by leveraging technology and operational efficiency to offer faster, more personalized service than larger suppliers. Adopting automation, digital inventory systems, and patient-centric practices allows small companies to reduce errors, improve patient satisfaction, and manage costs effectively.

Why is revenue cycle management important in DME?

Revenue cycle management (RCM) is essential because it ensures accurate billing, timely insurance claims, and consistent cash flow, all of which directly affect a DME company’s ability to operate efficiently. Inefficient RCM can lead to claim denials, delayed payments, and financial bottlenecks, which may slow down equipment delivery and disrupt patient care.

Can automation replace staff in a DME business?

Automation cannot fully replace human staff, but it significantly enhances operational efficiency by handling repetitive, time-consuming tasks. For example, automated intake forms, billing, and inventory tracking free employees to focus on patient care, personalized support, and strategic decision-making.

Combining skilled staff with intelligent automation creates a streamlined workflow that improves patient satisfaction, reduces errors, and allows DME businesses to scale without compromising service quality.

What is drop shipping in the DME industry?

Drop shipping in DME means the supplier ships medical equipment directly from the manufacturer or vendor to the patient, bypassing the need for storage and handling by the DME company. This approach reduces overhead costs, speeds up delivery, and allows providers to manage a wider variety of equipment without tying up capital in inventory.

How do I make my DME business more patient-centric?

Making a DME business patient-centric involves prioritizing the patient experience at every touchpoint, from intake to delivery and follow-up. Automating intake processes, improving communication about orders and insurance approvals, and streamlining payment collection reduces friction and keeps patients informed. Additionally, personalizing interactions, actively listening to patient feedback, and tailoring services to individual needs builds trust and loyalty.

A patient-focused approach not only improves satisfaction but also strengthens reputation, encourages repeat business, and enhances overall operational efficiency.

With over a decade of experience in medical software and hardware support, Alan combines technical expertise with hands-on client collaboration to help organizations achieve successful implementations.

Related Articles